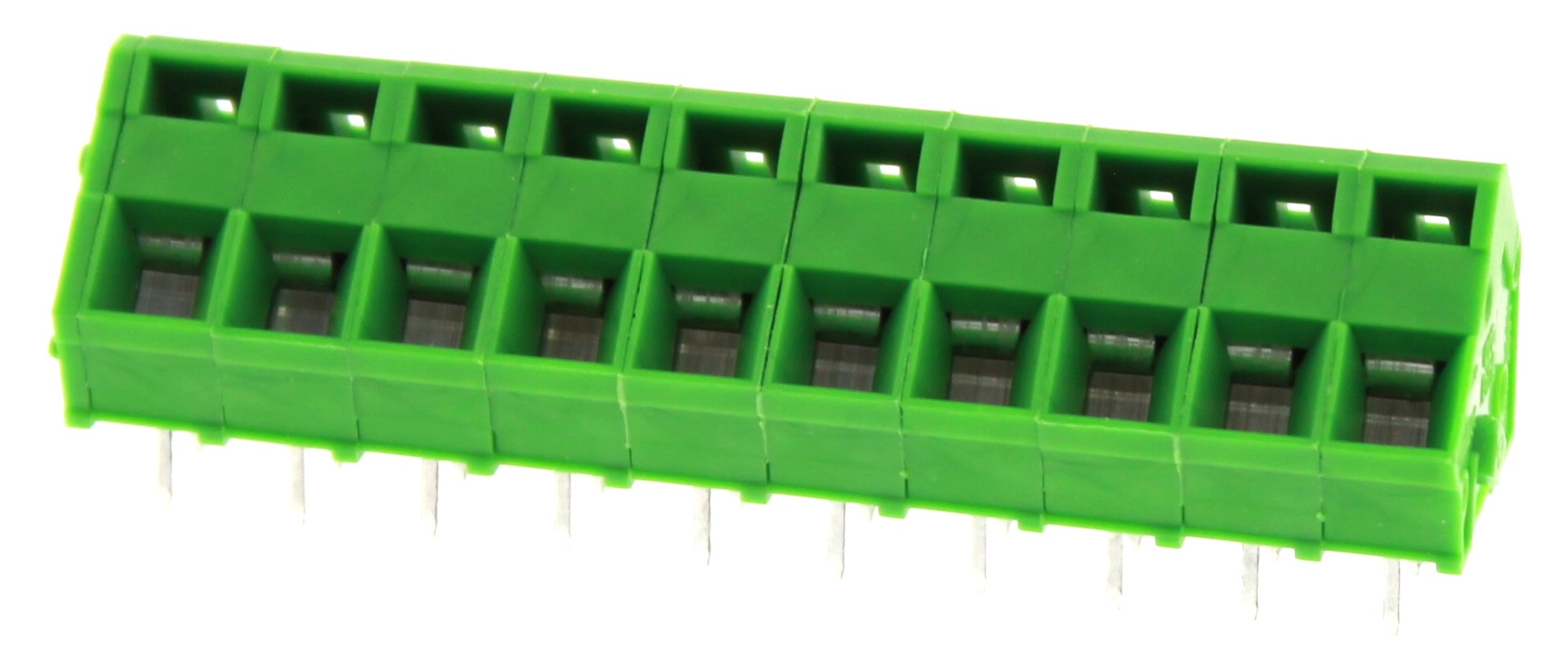

The wire protection principle is a user-related cost-effective alternative to the clamping yoke principle. The wire protection prevents the wire from shearing off and being pushed away.

Connection types

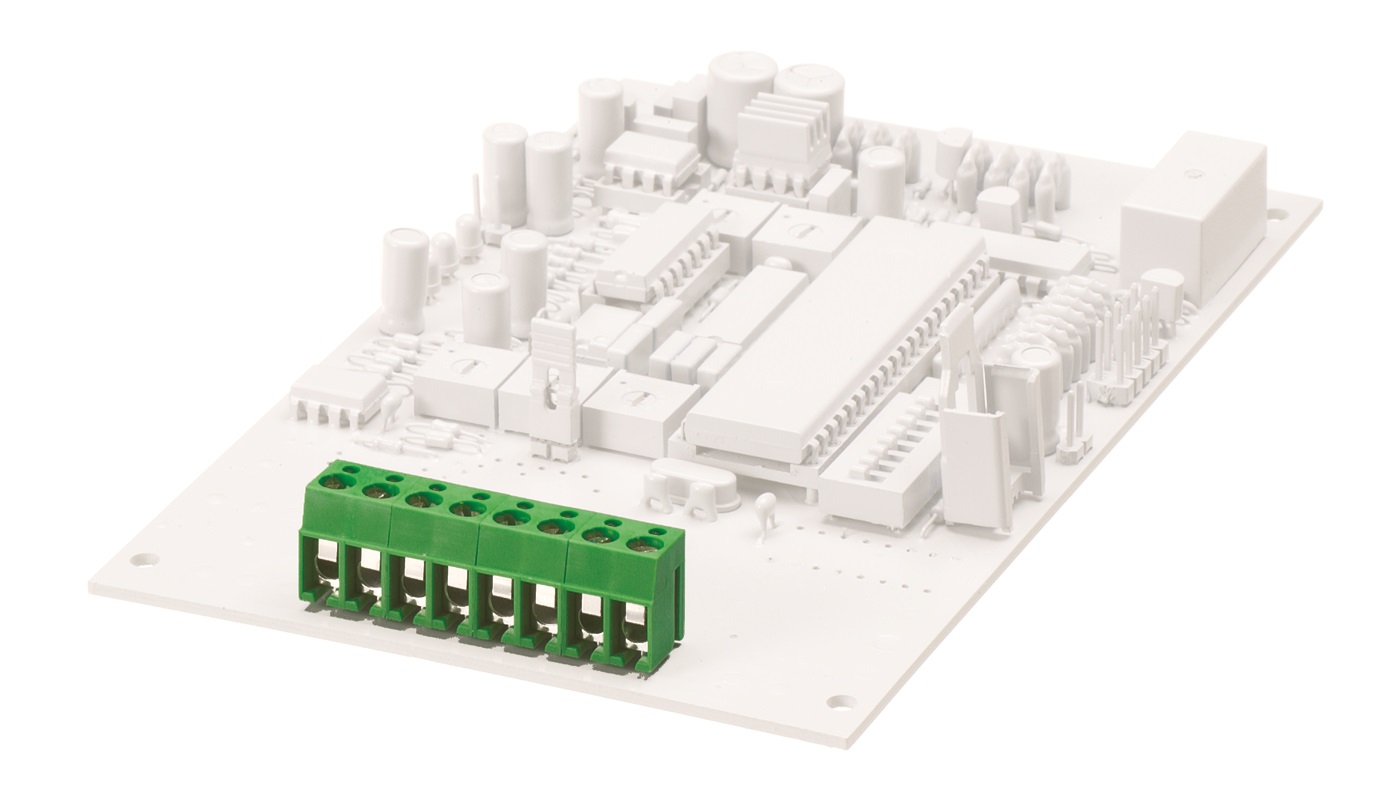

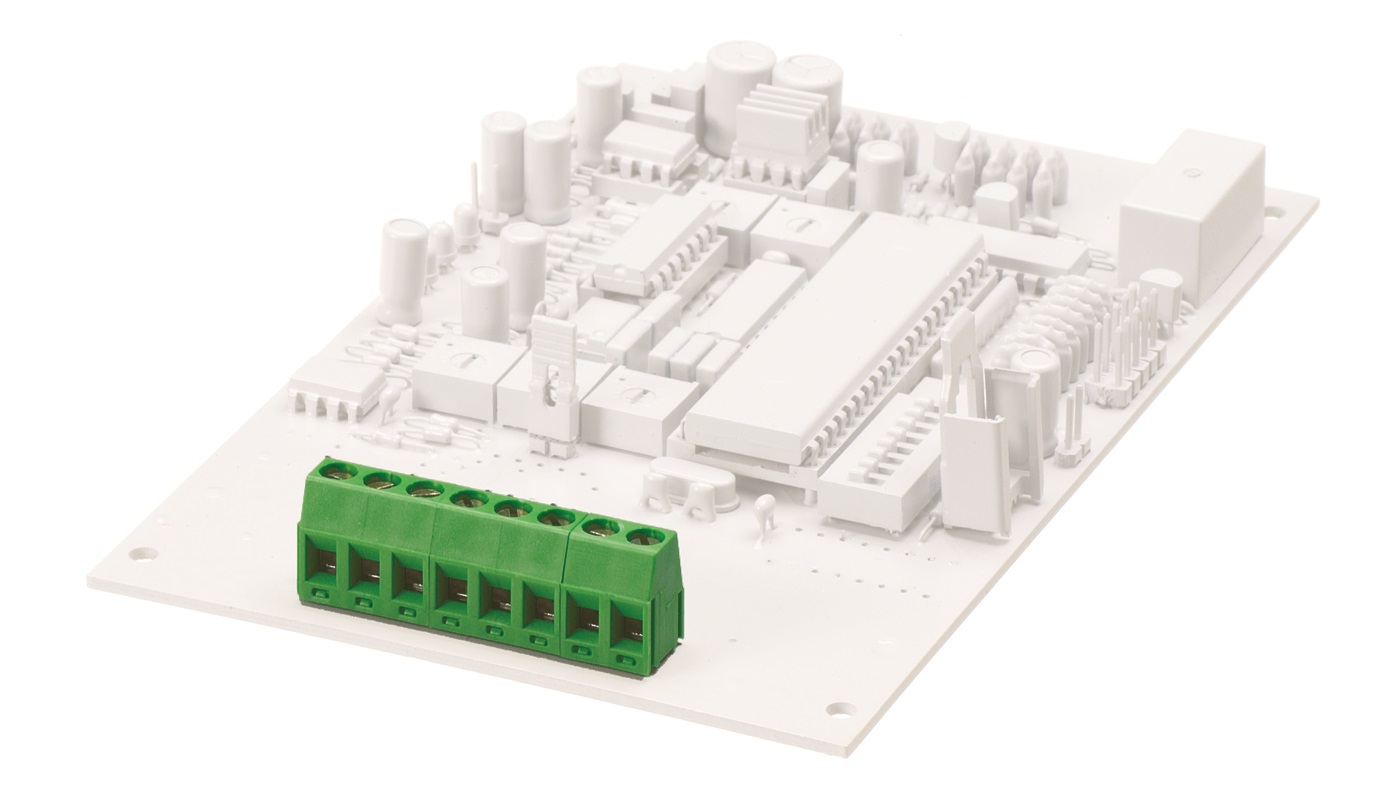

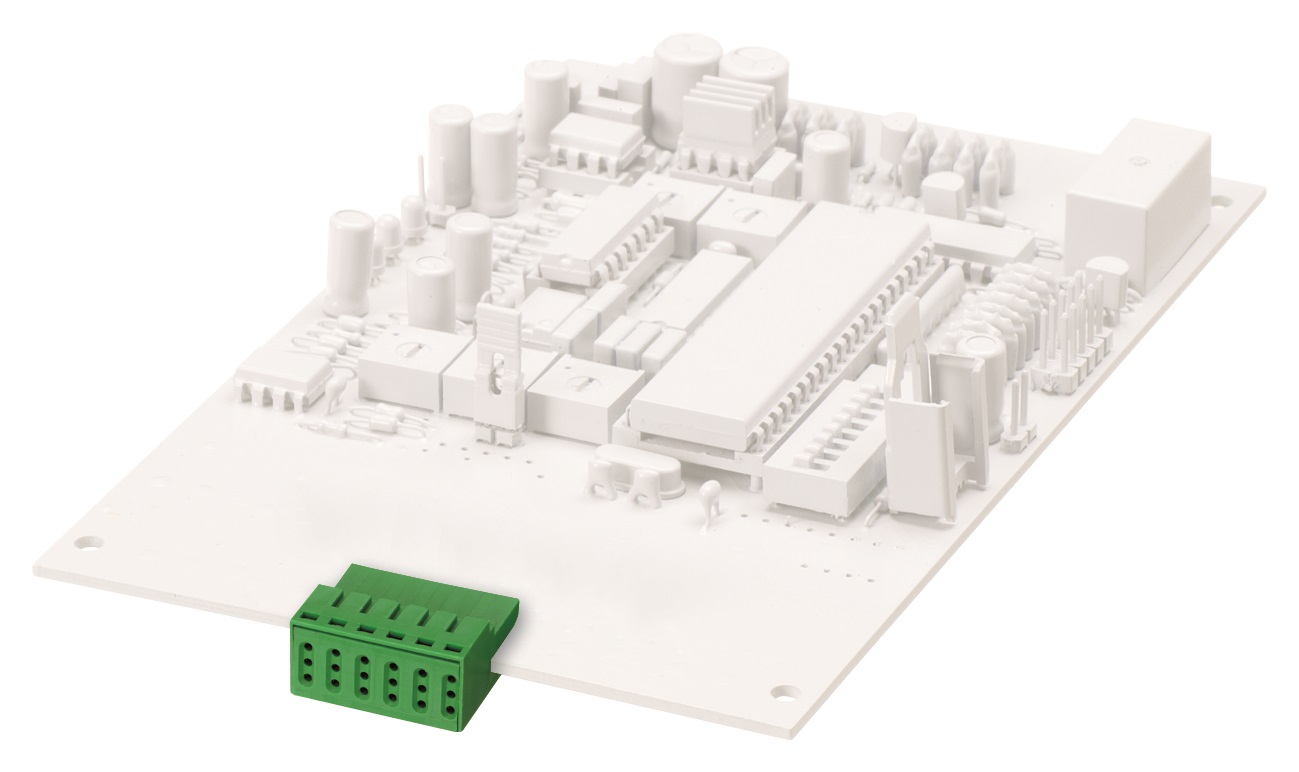

Solderable PCB terminal blocks or PCB PCB terminal blocks are used to connect stranded wires to components or circuits on the PCB. Our large range of PCB terminal blocks covers all connection types with push-in connections based on tension and leg springs, as well as screw fixings based on the wire protection, eccentric top or clamping yoke principle. The choice of the appropriate connection system depends on

the environmental conditions to which the PCB will be exposed in the subsequent application. For example, the push-in or tension clamp principle is particularly suitable for reliable contacting in the presence of vibrations, corrosive influences and strong temperature fluctuations. Depending on the design, the springs are actuated with a screwdriver, actuation tool or via an actuation lever. In addition, our terminal block series differ in their expandable or fixed block design. The PCB terminal blocks in modular design enable higher-pole terminal blocks to be assembled from 2-pole and 3-pole individual terminal blocks, depending on requirements and application, by means of dovetail connections - a clear plus for reduced stock-keeping. Alternatively, we offer series in fixed and up to 12-pole block design, which simplifies the configuration of more extensive applications. All the materials we use guarantee a permanently high clamping force and good electrical values.

Screw connection system Tension clamp principle

With the clamping yoke principle, the wire is indirectly pressed against the busbar (solder tag) via the screw and the clamping yoke. Here, the required contact force is created via the easy-to-use screw connection. With this system, a gas-tight, vibration-proof connection is made between the core and the busbar.

Eccentric Top Connection System Eccentric Top Principle

With the eccentric-top principle, the wire is guided into the clamping point parallel to the screwdriver in the direction of view. For certain mounting conditions, e.g. with small lateral distances in mounting frames, this system offers the operator very good accessibility to the connection level. This connection system is generally equipped with two solder tags.

Tension clamp connection system Tension clamp principle

The tension spring principle works in a similar way to the proven clamping yoke principle. With the tension clamp, the separation between mechanical and electrical function is also maintained. The tension spring made of high-quality, rust- and acid-resistant steel pulls the core against the galvanized copper busbar. Low contact resistance and high corrosion resistance are achieved by the tin surface of the busbar. Due to the balancing effect, this is maintained over time.

Push-in connection system Push-in principle

With the push-in principle, it is possible to insert solid conductors or fine-stranded cores with ferrules directly into the clamping point without tools. The push-in spring contacts the core against the busbar. When connecting fine-stranded wires without ferrules or to release the connections, the blade push lever must be operated.

Discover the CONTA-CLIP product world

Discover the CONTA-CLIP product world

With our digital catalog, you can get an overview of our service portfolio and identify suitable solutions for your requirement within a very short time:

Product Catalog